MEtalworking

Support technology

3D Printing

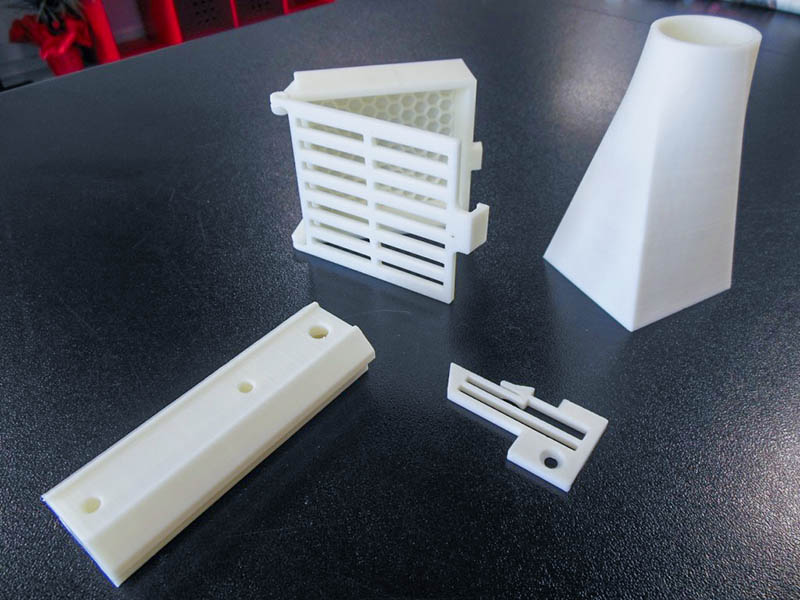

BOGGIANI RENATO SRL offers professional 3D printing, rapid prototyping, and small-batch production services, all carried out in-house to ensure project confidentiality and protection.

Our 3D printing technology creates three-dimensional objects directly from digital files, building them layer by layer. This process is perfect for producing complex shapes, minimizing material waste, and accelerating product development.

We primarily use ABS, a high-performance material that provides durability and strength, stability at room temperature, and precise processing thanks to its melting point above 100°C.

Laser Marking

aser marking allows for precise, permanent identification and customization of products. We offer third-party laser marking services directly in our facility, ensuring complete confidentiality.

Our system delivers fast, high-quality markings on a wide range of materials, from plastics to metals, with 3-axis control for crisp, deformation-free characters.

WHY CHOOSE LASER MARKING

- Sharp and uniform markings on text, logos, and geometric patterns.

- Durable and resistant to wear, heat, and chemicals.

- Suitable for plastics, metals, and many other materials.

OUR TECHNOLOGY

- High-quality hybrid laser for power, speed, and precision.

- 3-axis control for consistently perfect characters.

- Large working area (330 × 330 mm) with precise markings even at the edges.

Reverse Engineering

Another service offered by our Design Department is Reverse Engineering, a process that allows us to analyze an existing component in detail to reconstruct, redesign, or accurately replicate it.

Reverse Engineering enables us to determine the structure, dimensions, and design logic of a mechanical part even when the original technical drawings are missing.

We use a high-precision measuring projector to analyze the surfaces of the component at a microscopic level, tracing its sections and creating a complete and faithful 3D model.

This technology is especially useful in the textile and hosiery sectors, where older machines use components that are no longer in production and lack documentation. Reverse Engineering allows us to recreate these parts from scratch, ensuring operational continuity and replacing worn or hard-to-find components.