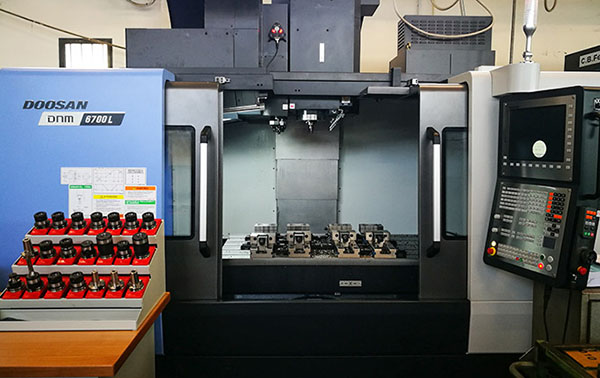

MEtalworking

Machine park

The machine park of our metalworking area is constantly evolving, and currently includes the following equipment:

- 3-AXIS MACHINING CENTERS;

- CNC NUMERICAL CONTROL LATHES (5-AXIS with the possibility of so-called ‘bar machining’);

- MANUAL LATHES AND MILLS;

- WIRE EDM;

- HYDRAULIC BENDER;

- WELDING AREAS;

- SEMI-AUTOMATED CUTTING AREAS;

SUPPLEMENTARY MACHINERY (tangential grinding machines, band saws, various sizes of bevelling machines, sandblaster, ultrasonic washing, heat treatment for small parts, and other specific machines for the various needs of the production phases)

- WELDERS (TIG, MIG and electrode);

- PLASTIC PROCESSING;

- ALUMINUM PROCESSING WITH ALL ANODIZING PROCESSES;

- STAINLESS STEEL WELDING.

In addition, available for the metalworking sector, we also have:

- 3D PRINTER, which allows to print three-dimensionally prototypes of future products at much lower costs compared to traditional methods for the production of samples.

PROFILE PROJECTORS, useful for detecting complex profiles from samples for which there are no drawings.

LASER MARKER, allows for high-quality markings at high speed, on a wide range of products, satisfying the needs of every type of industry. With this type of technology, it is possible to make markings on various types of materials, from plastic to extra-hard steel.

To best meet the needs of our customers, we also rely on nearby work realities in which we have full confidence, in order to provide a complete service, which may also include thick articles cut with the help of laser machinery or surface treatments such as anodizing on aluminum and heat treatments on steels.