“FIMAST represents an opportunity to personally discover the proposals of the major manufacturers worldwide and the most interesting curiosities in the textile, leather and footwear machinery sector, 360 degrees. Textile market companies showcase machines and accessories for spinning, chemical fiber production, roving, twisting, knitting, and hosiery.”

Source: provincia.brescia.it

This edition was expected to be very rich, due to the lengthening of the supply chain (which from production machines also embraces finished products) and the acceleration provided by Industry 4.0, which allowed us to bring “jewels” of innovation and technology to the fair.

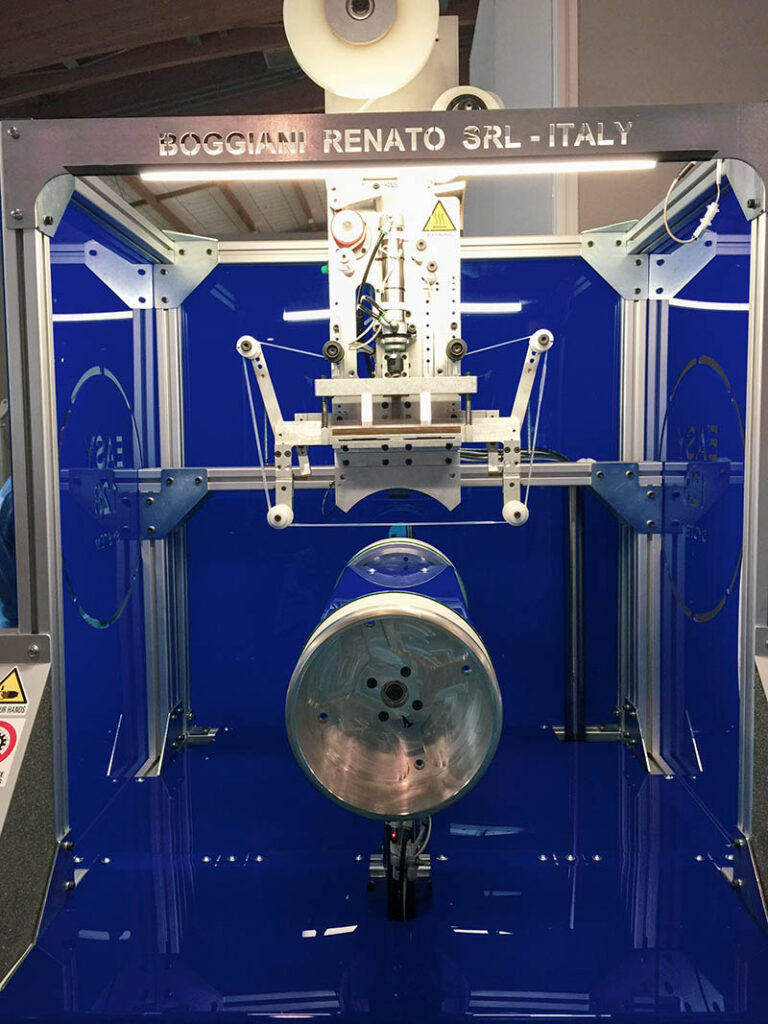

We, Boggiani Renato srl, were present as exhibitors and we looked to new horizons, further expanding our range of proposals, by adding to the hosiery assembly machines that we have been dealing with for years, the processing of clothing accessories, intimate apparel, seamless, technical clothing and medical and para-medical articles.

Another of our trade fair objectives was to be able to reduce hosiery production costs as much as possible.

At FIMAST 2018, we presented our new EASY 128 SYSTEM machine, equipped with highly innovative technology that allows for the finishing of tubular fabric parts (e.g. tights-socks-bracelets-gloves-anti-thrombotic stockings-bodies, and much more) by applying circular and non-transfer thermal gripping tape. It reduces processing times and costs by up to 70% compared to current application methods. Easy 128 System is easy to use, versatile and environmentally friendly.

Exhibited at the fair, we also brought our experience in the field of sewing and assembly of pantyhose, however, instead of focusing on an innovative machine, we focused on the innovation of a very important detail, namely a special COMFORT seam, created with a completely new GLC360 line with TCR2NG sewing needles made by us.

This type of pantyhose sewing and assembly line features some on-board machine innovations that allow the possibility of managing the machine EVEN WITHOUT THE APPLICATION OF THE TASSEL, that is, the possibility of using it both as an LC and as a GLC based on business needs. This is a very interesting feature, as it allows the company to have a pantyhose sewing and assembly line that can work indiscriminately on two different types of pantyhose, with the use of a single operator, greatly supporting cost savings and production flexibility. Last but not least, the pantyhose sewing and assembly line on display is equipped with an innovative and particular pantyhose transfer mode, with a high reduction in MACHINE STOPPAGE (compared to current machines on the market).

However, the heart of this pantyhose sewing and assembly machine lies in the UNION SPECIAL 39500 sewing heads, expertly transformed to create a comfortable, soft seam; combined with the innovations present on-board machine, they are able to make a finished pantyhose very comfortable.

Thanks to this edition of FIMAST, we had the opportunity to show our qualification, specialization, and particular attention to the evolution of market demands. Our specific activities regarding Union Special 39500 sewing machines, overhauling machinery for pantyhose assembly and sewing, such as TAKATORI, DETEXOMAT, and SOLIS sewing lines, are among our main tasks.

These are the main elements that distinguish us. We believe that these are fundamental characteristics to guarantee our products to our customers.