Hosiery

Revision, Maintenance and Repair of Sewing Machines for Hosiery

Thanks to the expertise of our technicians, we are able to provide not only repairs for hosiery sewing and assembly machines in case of malfunction, but also routine maintenance directly within the factory.

Our operators, specialized in the hosiery sector, offer professional technical support for a wide range of machines, including:

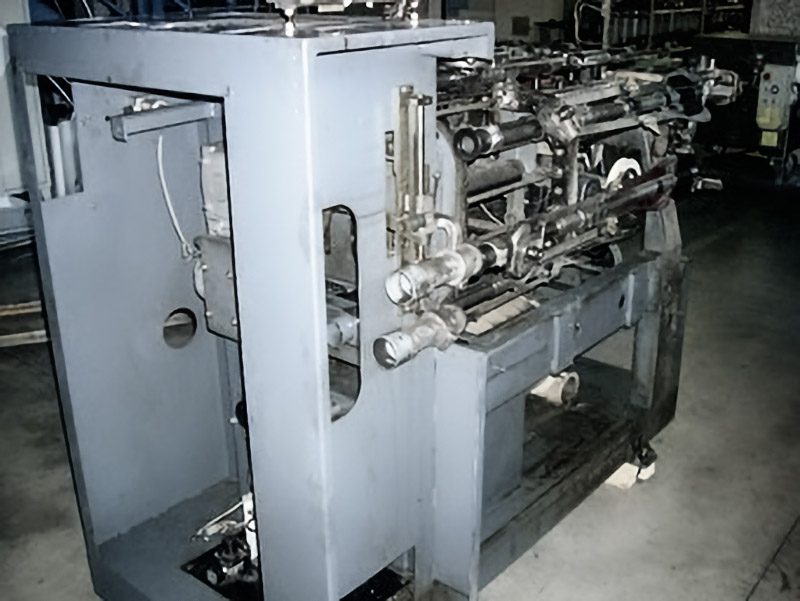

Union Special 39500 sewing heads

TAKATORI collant sewing and assembly machines, including Line Closer (LC), Gusset Line Closer (GLC), and Toe Closer (TC)

DETEXOMAT toe-closing machines

We carry out targeted interventions focused on specific issues, ensuring fast assistance and minimizing machine downtime during production. Additionally, we can schedule comprehensive on-site services at the client’s facility to address multiple issues simultaneously, maximizing productivity and efficiency.

Specialized Overhaul and Maintenance

Our high level of technical expertise is synonymous with reliability and precision, a quality that has led many clients to choose our machine overhaul services. The revision of hosiery sewing and assembly machines can be carried out at different levels:

Basic Overhaul. Includes a general inspection of the machine, replacement of worn or damaged components, and a final operational test.

Intermediate Overhaul .Includes a complete machine inspection, replacement of worn or damaged components, refurbishment of electrical and/or pneumatic systems, and a final operational test.

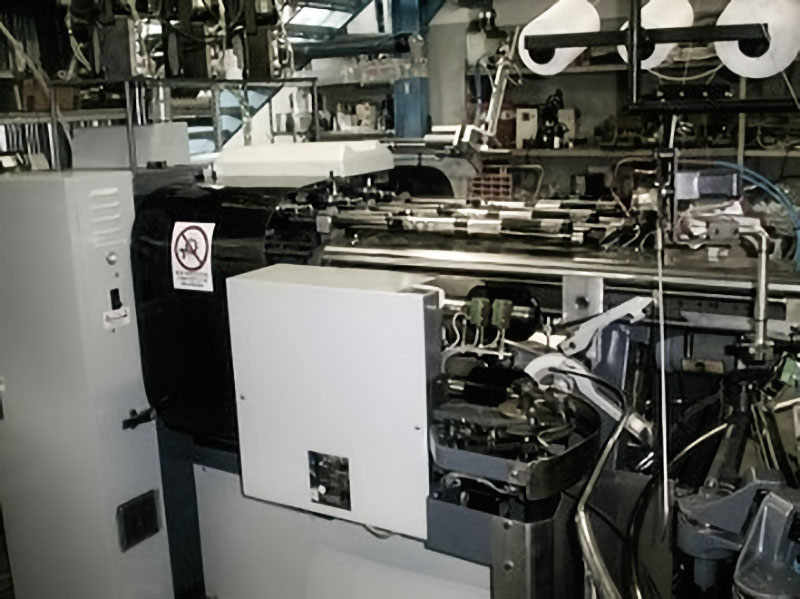

Advanced Overhaul .In addition to all the features of the Intermediate level, this includes full disassembly, deep cleaning, and repainting of the machine, as well as the implementation of innovative or additional technologies on-board. The result is a hosiery sewing machine that is practically like new, offering significant cost savings compared to purchasing a brand-new machine.

Overhaul with Transformation .This involves a complete renewal of the machine, transforming it into a fully customized machine tailored to the client’s specific production needs. In other words, a machine designed to meet 100% of your requirements.

International Support and Internal Organization

Boggiani Renato Srl also operates internationally, providing scheduled maintenance and installation/start-up services for hosiery sewing and assembly machines. However, all complete overhauls are carried out exclusively at our headquarters to ensure fast and effective interventions, even in case of unexpected issues. On-site, our technicians work in teams, with immediate support from our mechanical department whenever needed.

All hosiery sewing machine overhaul services are managed internally. We handle disassembly, cleaning, design, construction, and installation of new systems, including on-board machine enhancements to optimize production performance.

Clients can monitor the progress of the work at any time, ensuring transparency, quality, and professionalism.

We place great emphasis on precision, quality, and innovation, always selecting cutting-edge components that save energy without compromising machine efficiency.

Contact us today to request support, maintenance, or overhaul services for your hosiery sewing and assembly machines.