Hosiery

Revision, Maintenance and Repair of Sewing and Assembly Machines for Hosiery

Thanks to the qualification of our technicians, we are able not only to repair sewing and assembly machines for hosiery in case of failure but also to carry out ordinary maintenance within the hosiery factories.

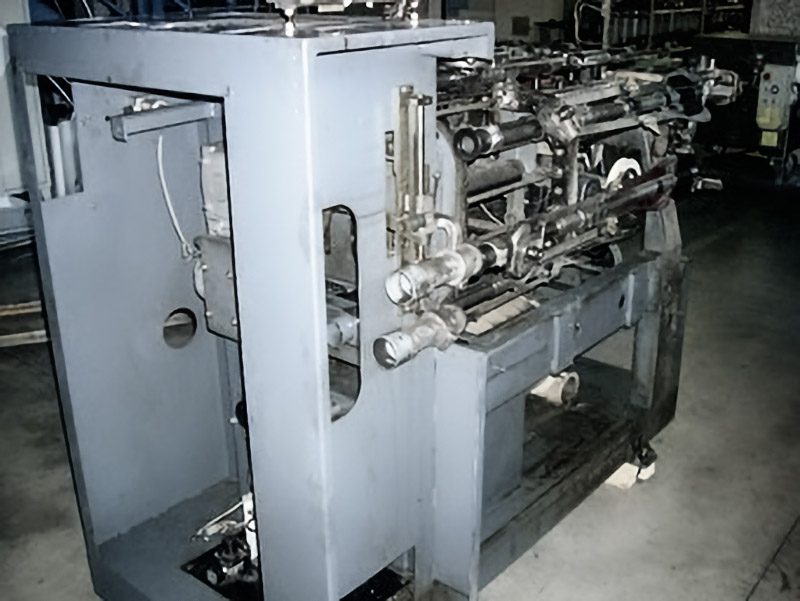

Our specialized operators in the hosiery sector provide SPECIALIZED TECHNICAL ASSISTANCE and are able to work on various types of sewing and assembly machines for hosiery:

- UNION SPECIAL 39500 sewing heads;

- TAKATORI sewing and assembly machines for hosiery, whether they are LINE CLOSERS (LC), GUSSET LINE CLOSERS (GLC), TOE CLOSERS (TC).

- DETEXOMAT sewing machines.

We carry out targeted interventions for single problems, for a quick assistance, minimizing the machine downtime during production. Similarly, we are able to plan significant interventions directly at the customer’s premises, in order to solve multiple problems at the same time.

High specialization and competence are synonymous with high reliability, a prerogative that has led many customers to use our REVISION services.

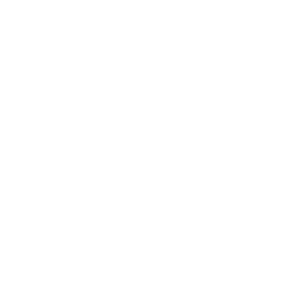

Revision for sewing and assembly machines for hosiery can be of different types.

- “BASIC” LEVEL REVISION involves checking the machinery, replacing worn and/or damaged parts, and a final work test;

“INTERMEDIATE” LEVEL REVISION involves checking the machinery, replacing worn and/or damaged parts, complete refurbishment of the electrical and/or pneumatic systems, and a final work test. In this case, innovation interventions may also be carried out. This type of intervention is indicated for TAKATORI Line Closers (LC) – TAKATORI Gusset Line Closers (GLC) – TAKATORI Toe Closers (TC) – DETEXOMAT Toe Closers sewing and assembly machines.

“ADVANCED” LEVEL REVISION involves complete disassembly and repainting of the machine, thorough cleaning, replacement of worn and/or damaged parts, complete refurbishment of electrical and pneumatic systems, on-board implementation of innovative and/or additional technologies compared to what was originally present, and work is completed with a final work test. Thanks to this, the customer can have a practically new machine, with an increase in productivity and an update of the system with the latest technological standards. This type of intervention is indicated for TAKATORI Line Closers (LC) – TAKATORI Gusset Line Closers (GLC) – TAKATORI Toe Closers (TC) – DETEXOMAT Toe Closers sewing and assembly machines;

We are also able to carry out TRANSFORMATION REVISION interventions, renewing the customer’s sewing and assembly machine for hosiery, transforming it into a completely new machine. Within our BLOG, in the FAIRS AND EXHIBITIONS section, it is possible to better understand what a transformation for TAKATORI-based sewing and assembly machines for hosiery consists of.

We also work abroad, where we carry out scheduled maintenance and installations/launches, as far as revisions are concerned, they are carried out exclusively within our premises, since the unexpected is always around the corner and we do not like to be unprepared; at our premises, our technicians can work in a team, receiving the support of the mechanical department if necessary, at any time.

All revision interventions for sewing and assembly machines for hosiery are managed internally at BOGGIANI RENATO SRL, including disassembly, cleaning, design, and installation of new systems, including any on-board machine implementation study.

The customer can check the progress of the work at any time, as a guarantee of transparency and professionalism of our work.

We place great emphasis on precision, quality, and innovation, which is why we are always searching for cutting-edge components that allow us to save energy without sacrificing efficiency.